All About Plastic Laser Welding

Posted by: Damon Webster | Posted on: August 24, 2019Commonly used joining techniques such as ultrasonic and gluing welding has now been replaced with laser welding in many industrial and manufacturing fields. This modern day plastic joining process is free from solvents and particles, highly flexible, and it even provides strong connections without damaging or making your work surface. Hence, consider plastic laser welding for your business or projects needs.

This technique is the perfect choice when you need accuracy and precise control to protect the internal components. You can also use this to weld challenging geometries successfully. Today, such machine has gained excellent reputation among many industrial and manufacturing fields, and most of them are even replacing their old methods with this.

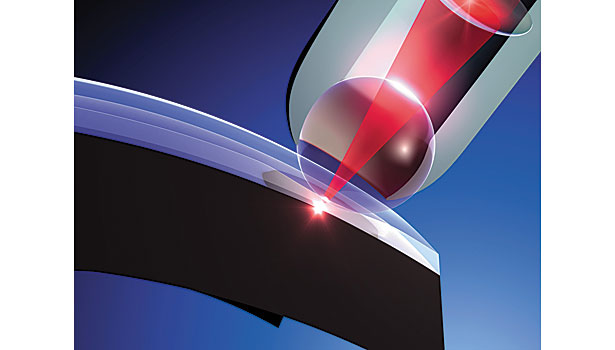

Plastics that utilizes such method will be joining two thermoplastic together, an absorbing partner and transparent plastic. The beam punctures the upper transparent component, while the absorbing component is melted, bonding transparent plastic. If the process is done properly, expect a secured and leak free outcome.

With overlapping welding, weld will be generated inside without releasing any particles. This creates a high quality and almost invisible weld. Heat input has only minimal impact towards your components, making it possible to create welds even in vicinity with electronic components. Since this allows you to weld without using any solvents, industrial waste is reduced, saving you on cost.

Main techniques used in laser welding. Contour, for large or three dimensional parts. Contour moves with just one single pass. Mask would need to utilize movable wide beams and this also has a shield protection area. Quasi simultaneous uses small beams which passes over joints several times. Simultaneous uses multiple beams at the same time over the joint.

People are accustomed to plastics as these could be found anywhere, in cars, shelves, medical technology, supermarkets, etc. These areas join plastic components together. This particular technique and tool is needed and universally used for those who wants a high quality, stress free, and reliable process. Assuring high quality works or products, which is why many are now switching to this.

There are companies that helps perform welding processes for projects, and you might want to consider getting such services. Your project is special, so you have to look for company who will gladly take your assignments with the goal of achieving the best possible outcome. Here is how you can find the right company that offers such services.

Ask recommendations. Ask recommendations from your trusted relatives, friends, and colleagues. You might know someone who is currently doing a certain project that involves such machine, and they might be able to provide you with good recommendations. For those who can provide you with such recommendations, you might want to ask questions from them regarding their experience.

Look for someone who will not only weld for you, but would also recommend you designs and materials that will allow you to develop efficient products that are technically and economically superior to both conventional designs and materials. A company that can provide you with the right machine and would calculate the most favorable process parameters in your place.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Comments are Closed